产品参数

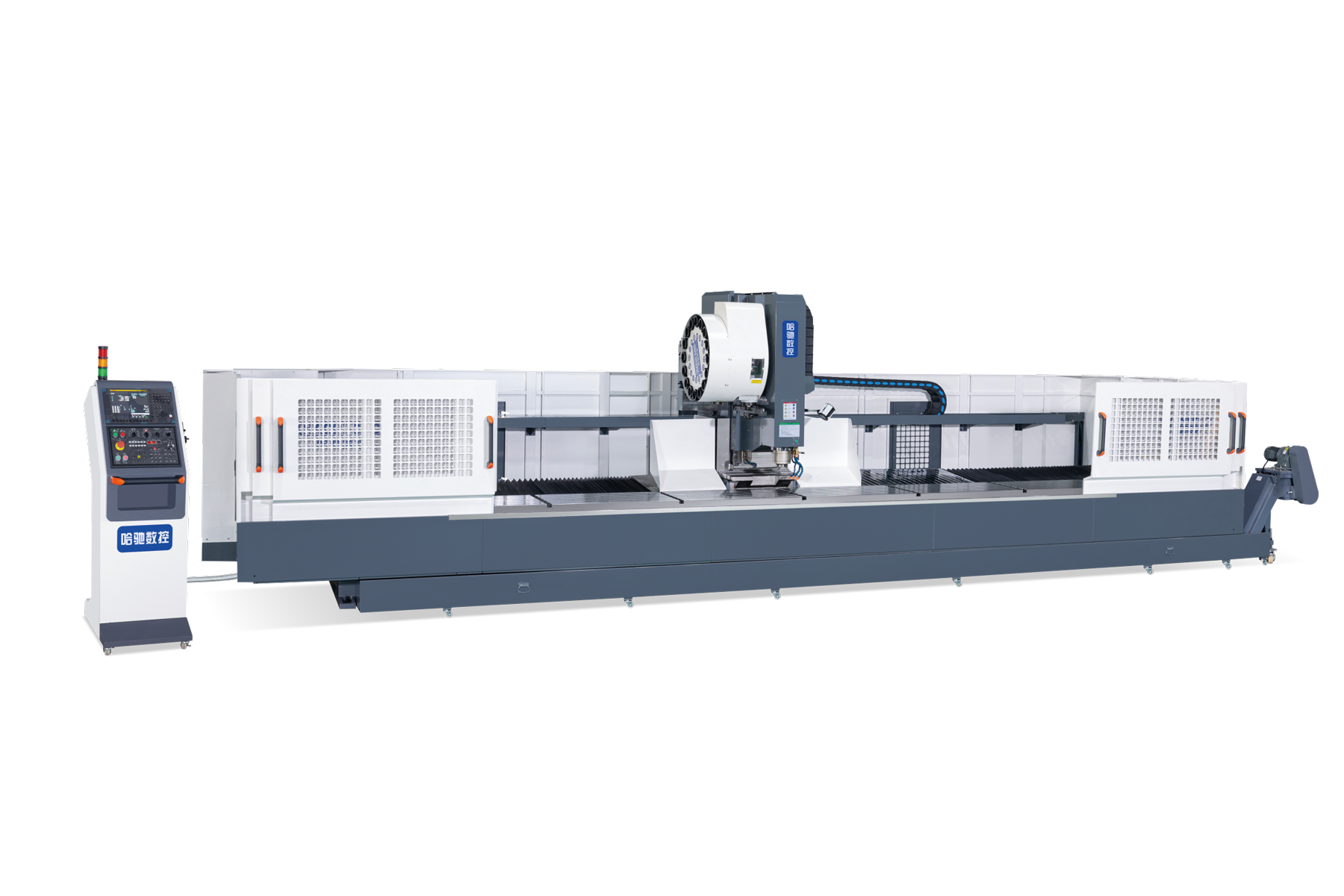

Equipment Introduction: This equipment is an automatic composite profile processing center integrating milling, drilling and tapping. It is suitable for processing steel, aluminum, copper metal and non-metal profiles of various lengths. It is especially suitable for processing heavy aluminum profiles and steel profiles.

Configuration introduction: BT50 spindle taper hole with diameter of 155mm is used; X/Y/Z axis is equipped with high rigidity 45# roller linear rail; imported high-end control system; high-power servo motor, the equipment is super rigid.

Application areas: Echanical parts, rail transit, aerospace, military machinery, etc.

Welding frame bed HD 2500/HD 4500/HD 6500

HD Series Technical parameter table

| Project | Unit | Parameter |

| TRAVELS | X Axis | mm | 2500/4500/6500( other lengths can be customized) |

| Y Axis | mm | 600 |

| Z Axis | mm | 600 |

| The distance from the nose of the spindle to the end of the table | mm | 150 |

| Move | Moving speed X/Y/Z | m/min | 60 | 28 | 28 |

| Cutting feed rate X/Y/Z | mm/min | 15000 | 15000 | 15000 |

| PRECISION | Cutting feed rate X/Y/Z | mm | 0.03 | 0.02 | 0.02 |

| Repeat positioning accuracy X/Y/Z | mm | 0.02 | 0.02 | 0.02 |

| Spindle | Maximum speed | rpm | 8000 |

| Spindle taper | | BT50 Standard taper |

| Spindle taper | | BT50 |

| PORWER OF MOTOR | Driven motor | Power X/Y/Z | mm | 3.0/3.0/3.0 |

| Spindle driven motor | Power | KW | 15 |

| | | | | |

| Project | Unit | Parameter |

| TOOLS | Tool changer format | | Disc type |

| Spindle taper | | BT50 |

| Tool capacity | sec | 16/24 |

| Tool change time | sec | 2.1 |

| Pull studs format | | 45° |

| LUBRICATING SYSTEM | Lubricating system | | Automative lubricating |

| Cooling system | | Water cooling system |

| POWER | Electricity | KVA | 30(380V、50HZ)KVA |

| Gas source | mpa | 0.6Mpa-0.9Mpa |

| MECHNICAL SPECIFICATION | Operating system | | FANUC/MITSUBISHHI |

| Overall height | | About 3000 |

| Machine width | mm | About 3000 |

| Overall length | mm | About 6600-10800 |

| Area | mm³ | About 6600-10800*3000 |

| Weight | KG | About 10000-17500KG |