Product parameters

Equipment Introduction: This equipment sets milling, drilling, tapping as one of the automatic composite profile machining center

Applicable profile:Suitable for processing various lengths of copper profiles, thick aluminum profiles, etc

Configuration introduction: Equipped with double spindle, double moving column, double operating cabinet, imported high-end control system, optional automatic chip removal machine

Application: New energy profile processing, home appliance aluminum alloy parts, high-end doors and Windows, curtain wall profile processing

Feature overview: Big roller rail, super rigid. Large diameter precision lead rod,Y-axis/Z-axis large stroke (Y-axis 550-800mm; The Z axis 550-700mm)

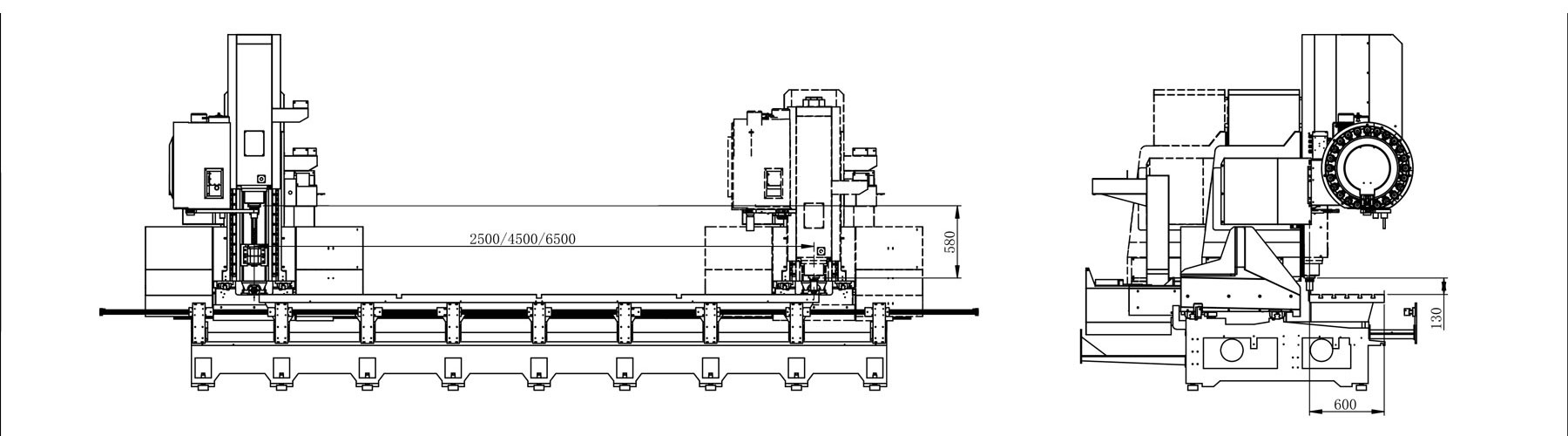

Casting lathe bed HGE4500C2W / HGE6500C2W

HGE-C2W PARAMETER TABLE HGE-C2W Series Technical parameter table

| Project | Unit | Parameter |

| TRAVELS | X Axis | mm | 4500/6500 |

| Y Axis | mm | 600 |

| Z Axis | mm | 600/700 |

| The distance from the nose of the spindle to the end of the table | mm | 130 |

| Move | Moving speed X/Y/Z | m/min | 60 | 28 | 28 |

| Cutting feed rate X/Y/Z | mm/min | 15000 | 15000 | 15000 |

| PRECISION | Cutting feed rate X/Y/Z | mm | 0.03 | 0.02 | 0.02 |

| Repeat positioning accuracy X/Y/Z | mm | 0.02 | 0.02 | 0.02 |

| Spindle | Maximum speed | rpm | 12000 |

| Spindle taper |

| BT40 Standard taper |

| Spindle taper |

| BT40 |

| PORWER OF MOTOR | Driven motor | Power X/Y/Z | mm | 3.0/3.0/3.0 |

| Spindle driven motor | Power | KW | 11 |

|

|

|

|

|

|

| Project | Unit | Parameter |

| TOOLS | Tool changer format |

| Disc type |

| Spindle taper |

| BT40 |

| Tool capacity | sec | 24 |

| Tool change time | sec | 1.8 |

| Pull studs format |

| 45° |

| LUBRICATING SYSTEM | Lubricating system |

| Automative lubricating |

| Cooling system |

| Water cooling system |

| POWER | Electricity | KVA | 25(380V、50HZ)KVA |

| Gas source | mpa | 0.6Mpa-0.9Mpa |

| MECHNICAL SPECIFICATION | Operating system |

| FANUC/MITSUBISHHI |

| Overall height |

| About 3100 |

| Machine width | mm | About 3000 |

| Overall length | mm | About 8100-11000 |

| Area | mm³ | About 8100-11000*3000 |

| Weight | KG | About 16000-19000KG |