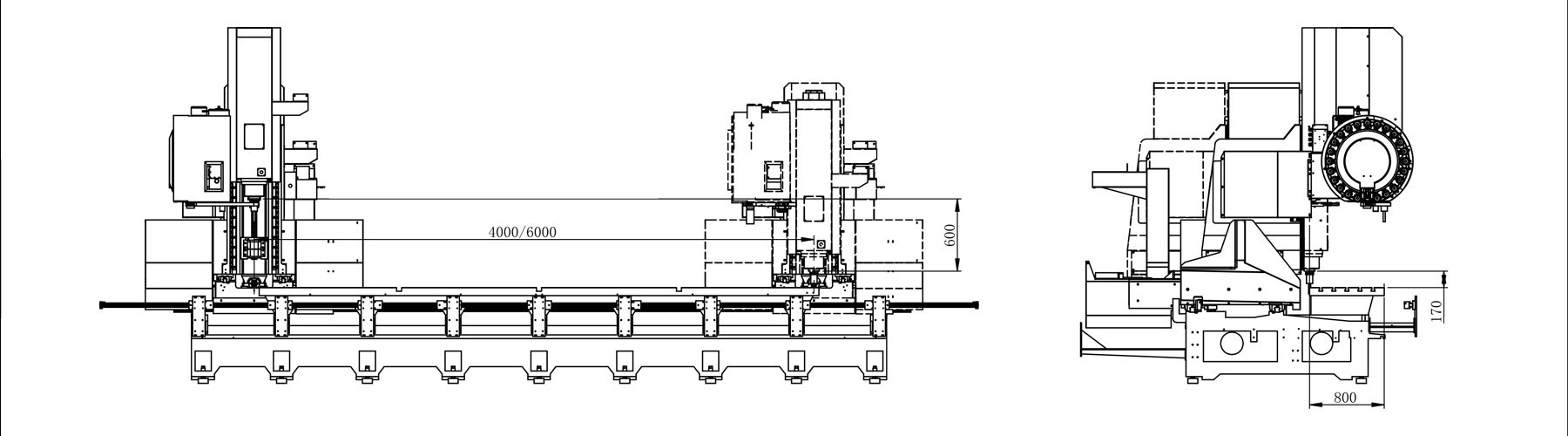

Equipment Introduction:This equipment is an automatic composite profile machining center integrating milling,drilling and tapping.It is suitable for processing various lengths and extra widths of steel,aluminum,copper metal and non-metallic profiles

Configuration introduction:BT40 spindle taper hole with diameter of 150mm is used;X/Y/Z axis is equipped with high rigidity 45#roller linear rail;imported high-end control system;high-power servo motor,the equipment is super rigid

Application areas:echanical parts,rail transit,aerospace,military machinery,eto