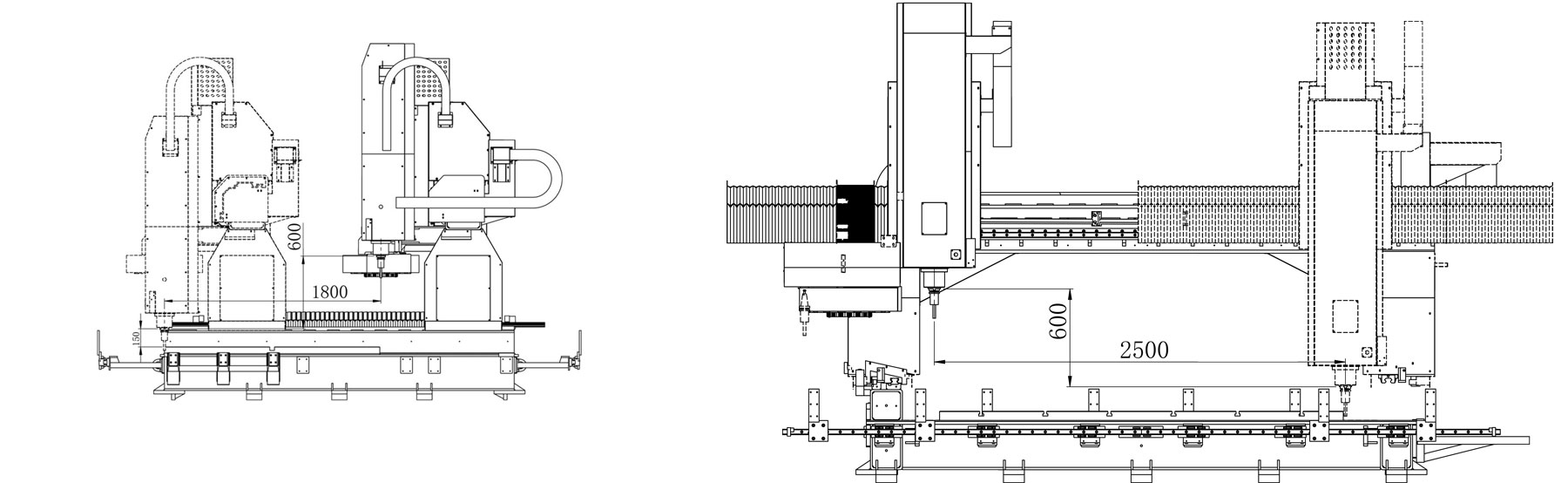

Equipment Introduction: This equipment SETS milling, drilling, tapping as one of the automatic composite profile processing center, suitable for various lengths of copper, aluminum and nonmetal profiles, plate processing

Configuration introduction: Use 120mm diameter BT40 spindle, imported high-end CNC system, equipped with automatic chip removal machine

Application: New energy vehicle battery tray, plate processing, rail transit, etc

Feature overview: New energy vehicle parts processing special, processing parts range, high processing accuracy, fast speed, double chip removal machine design for easy chip removal